verview

Essential details

Place of Origin:

Jiangsu, China

Brand Name:

THIM

Model Number:

FXBW-33/8

Type:

Insulator

Material:

Composite Polymer

Application:

High Voltage, High voltage line facilities

Rated Voltage:

33KV

Tensile Strength:

8KN

Product name:

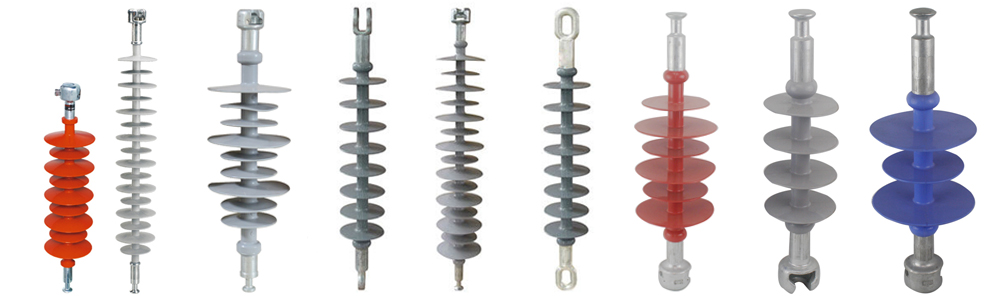

Electric 33kv Composite Polymer Suspension Insulator Strain Insulator

Color:

Customized

Certification:

IEC,ISO,ASTM,ANSI,GB/T

Size:

Customized Size

Feature:

High Temperature Resistance

Advantage:

Good pollution/aging resistance,high mechanical strength

Keyword:

400kv composite suspension insulator

OEM:

Available

Sample:

Sample Available

Supply Ability

Supply Ability

100 Piece/Pieces per Day Electric 33kv Composite Polymer Suspension Insulator Strain Insu

Packaging & delivery

Packaging Details

Electric 33kv Composite Polymer Suspension Insulator Strain Insulator:

cartons or according to customer's

Port

shanghai

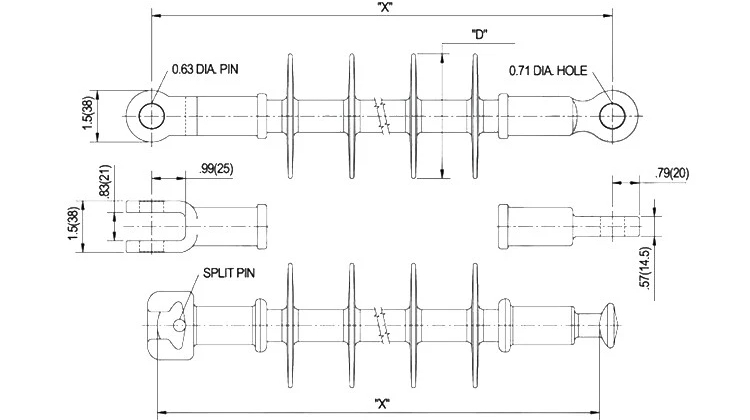

Product Information

Composite Suspension Insulator

This product is especially suitable for polluted area ,high mechanical tensile load and large span and compact line.It has the feature of light weight,small volume,not easily broken,,high mechanical strength, high pollution resistant,good aging resistance,high anti explosive and others.

Product structure and advantages

Our company specially produces composite insulator for power transmission line, the important structure is made of shed housing, epoxy fiberglass core and metal end fittings. The surface of terminal end fittings is covered with zinc coating(hot-dip galvanization) for corrosion protection. Compared with same type ceramic and glass insulator, silicone rubber insulator has the following advantages:(1)Small volume, light weight(is 1/7~1/10 times than ceramic insulator in the same voltage), sheds have good elasticity, not broken, convenient transportation and installation, economy.

(2)High mechanical strength. FRP ROD has high tensile strength, which is 5-10 times than ceramic materials, for core is small cross section, which makes the products small size, light weight, high tensile strength, and easy to manufacture more than 300KN large tons insulators.

(3)High antifouling property, good aging resistance performance, the sheds made of silicone rubber injection mold has good hydrophobicity and migration, which makes insulator high anti pollution flashover voltage and good electric corrosion resistance.

(4)Easy installation and maintenance, can greatly reduce outage loss which cause due to maintenance and maintenance charges which cause by manual labor intensity.

(5)Simple production process, short delivery time.

Detail Display

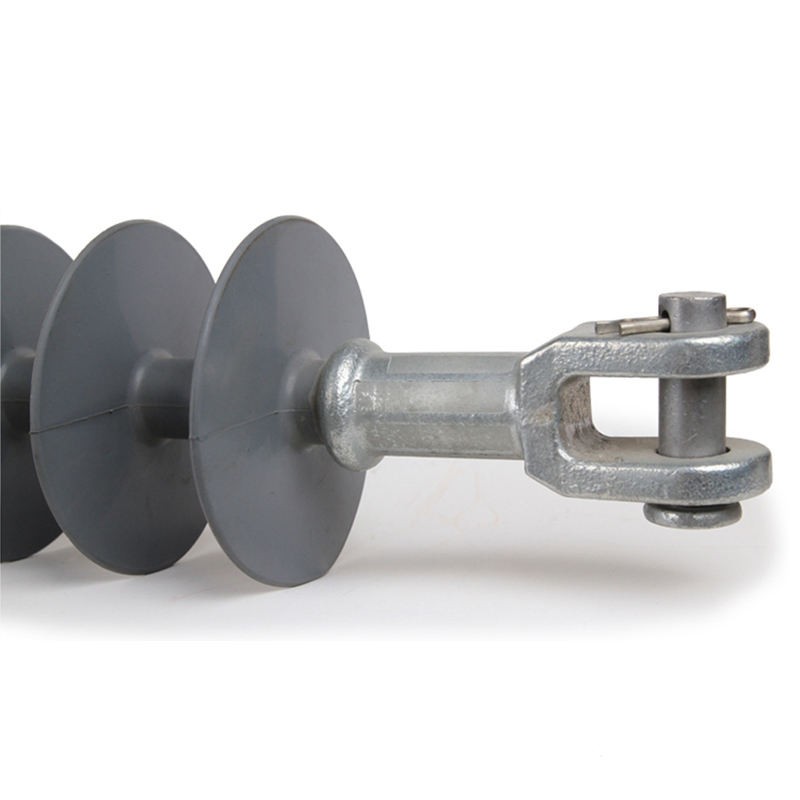

Composite Suspension Insulator——

Dead End Insulator

1.Shed connected with core by integral forming

2.metal end fittings, core and sheds connected by new crimping process

3.The thickness of housing > 3mm, uniform thickness, confirm to IEC Standard

4.Acid resistant, high temperature resistant of epoxy fiberglass core

5.The material of metal end fittings is used with hot galvanization and technology of rare earth aluminum coating to avoid coating shedding when crimping, prolonging the service life of the product.