Overview

Essential details

Applicable Industries:

Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Food & Beverage Shops

Showroom Location:

Egypt, Turkey, Mexico, Morocco

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

New Product 2020

Warranty of core components:

1 Year

Core Components:

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Condition:

New

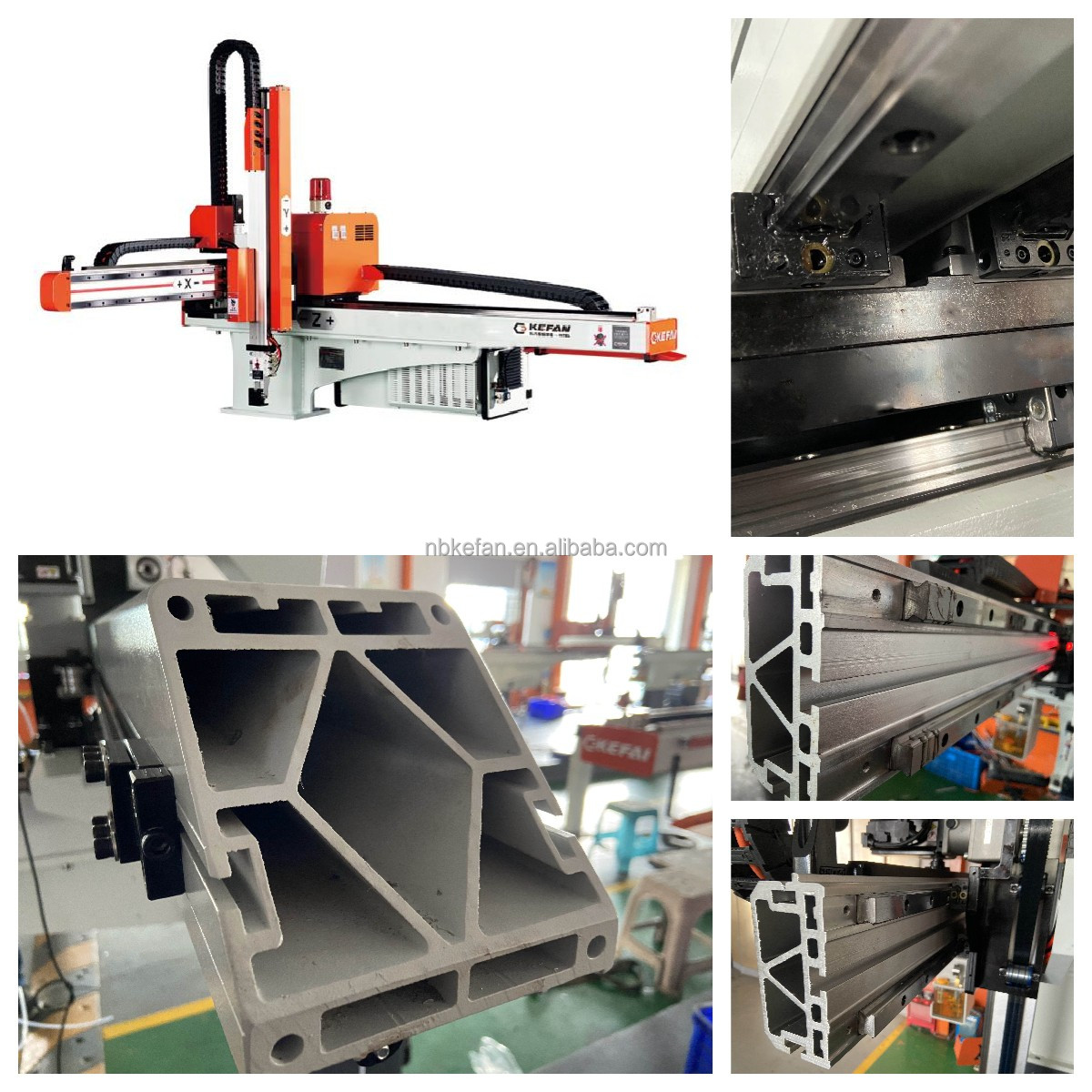

Vertical Travel(mm):

1100mm

Horizonal Travel(mm):

1850mm

Place of Origin:

Zhejiang, China

Brand Name:

KEFAN

Weight:

255 kg

Dimension(L*W*H):

2310X1550X1720mm

Power:

220v, 50/60HZ

Warranty:

1 Year

Weight (KG):

255 kg

Suitable Machine Range:

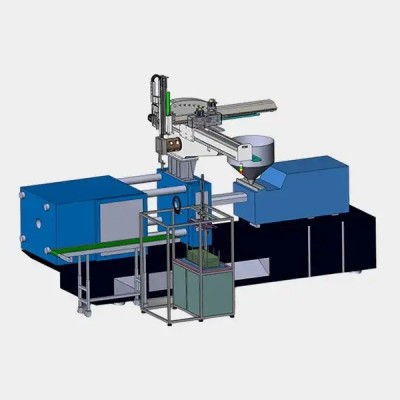

260-400T

Driving Method:

AC Servo Motor

Maxi load:

5

C Axis Posture Torque:

35 Nm

Linear Position Repeatability:

+/-0.1 mm

Working pressure:

5-7 kgf/cm

Consumption:

1.5 NL/cycle

Maximum Power:

1.9 Kw

Supply Ability

Supply Ability

7000 Set/Sets per Year

Packaging & delivery

Packaging Details

Export standard package

Port

NINGBO /SHANGHAI /XI'AN

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 15 To be negotiated

Specification