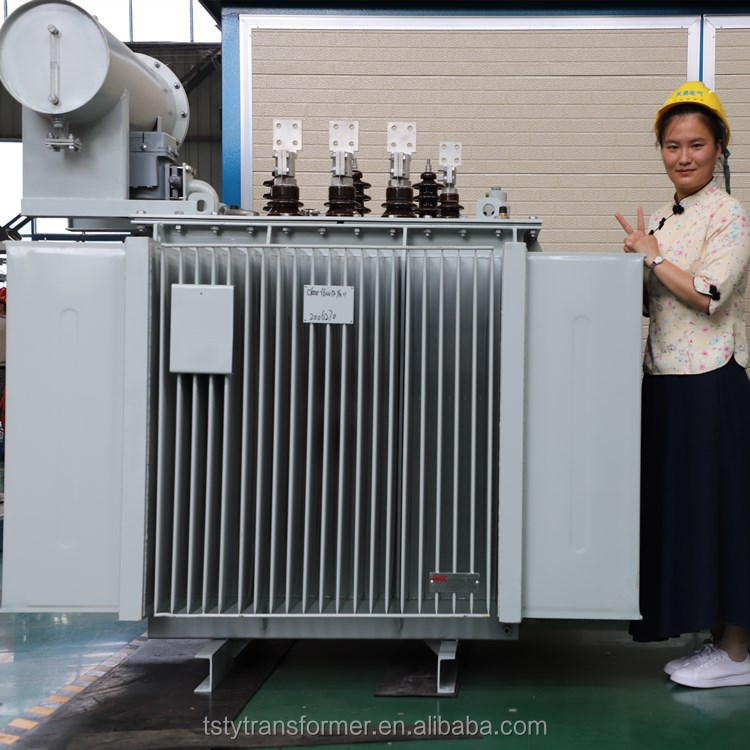

Price of Electric Transformer Oil Transformers for Sale in Indonesia Oil Electric Filled Cooled Dist

| Price | ¥1100.00/Piece |

| Min quantity | 1Piece |

| Quantity | 10000000Piece |

Product Description

* This model is produced in accordance with Chinese national GB standards and the international IEC standards.

* It uses oil as the main insulation means of the transformer, and relies on oil as the cooling medium, such as oil-immersed natural cooling, oil-immersed air cooling, oil-immersed water cooling and forced oil circulation, etc.

* The main components: iron core, winding, fuel tank, oil pillow, breathing apparatus, explosion-proof tube (pressure release valve), radiator, insulating casing, tap switch, gas relay, thermometer, oil purifier, etc.

* Widely used in high-rise buildings, commercial centers, subways, airports, stations, industrial and mining enterprises, drilling platforms and oil production platforms; especially suitable for use in flammable, explosive and other harsh environments.

Product Features:

The S11 series fully sealed oil-immersed power transformer developed and produced by the company has the advantages of low loss, low noise and high efficiency, which can achieve good energy-saving effects and reduce pollution.

Compared with ordinary oil-immersed transformers, fully sealed transformers eliminate the oil conservator. The change of oil volume is automatically adjusted and compensated by the elasticity of the corrugated sheet of the corrugated oil tank. The transformer is isolated from the air to prevent and slow down the deterioration of oil and insulation aging so as to enhance operational reliability, and maintain normal operation without maintenance.

1.The transformer core is laminated with imported cold-rolled silicon steel sheets, which greatly reduces the no-load loss and no-load current. The core is bound to ensure the tightness of the core and reduce noise.

2.High and low voltage windings are made of oxygen-free copper, and low voltage windings of 500kVA and below adopt double-layer cylindrical structure. 630kVA and above adopt double helix or four helix structure, high voltage winding adopts multilayer cylindrical structure.

3.The transformer connection group uses Dyn11 to reduce the impact of harmonics on the power grid and improve the quality of power supply.

4.The transformer is a fully sealed structure, which prolongs the service life, does not require hanging cores and maintenance.

5.The measured noise value is lower than the standard. After this series of transformers have been transported normally, the relevant parts can be installed without core inspection, and they can be put into operation once the acceptance test is qualified.

Product Standard:

GB 1094 Power Transformer

GB/T 15164 Oil-immersed Power Transformer Load Guide

GB/T 6451 Three-phase Oil-immersed Power Transformer Technical Parameters and Requirements

GB 2536 Transformer Oil

GB 311.1 Insulation Coordination of High-voltage Power Transmission and Transformation Equipment

GB 10237 Insulation Level of Power Transformer and Air Gap of External Insulation in Insulation Test

DL/T 572 Transformer Operation Regulations

Applicable Environment:

1.High ambient temperature: +40℃

2.Low ambient temperature: -25℃

3.Altitude: <1000m

4.Monthly average relative humidity: 90% (20℃)

5.Installation location: Install in a place where there is no fire, explosion hazard, serious pollution, chemical corrosion and severe vibration, indoors or outdoors.

Model Implication:

Technical Parameter:

| Technical Parameter for S11 Series 20kv No-load Voltage Regulation Transformer | ||||||||

| Rated Capacity (KVA) | Voltage Combination | Connection Group Symbol | No-load Loss R(W) | Load Loss R(W) | Impedance Voltage(%) | No-load Current (%) | ||

| High Voltage(KV) | Tapping Range of High Voltage | Low Voltage (KV) | ||||||

| 30 | 20 | 0.4 | 90 | 690/660 | 5.5 | 2.1 | ||

| 50 | 130 | 1010/960 | 2 | |||||

| 63 | 150 | 1200/1150 | 1.9 | |||||

| 80 | 180 | 1440/1370 | 1.8 | |||||

| 100 | 200 | 1730/1650 | 1.6 | |||||

| 125 | 240 | 2080/1980 | 1.5 | |||||

| 160 | Dyn11 | 290 | 2540/2420 | 1.4 | ||||

| 200 | ±5% | Yzn11 | 340 | 3000/2860 | 1.3 | |||

| 250 | ±2x2.5% | Yyn0 | 400 | 3520/3350 | 1.2 | |||

| 315 | 480 | 4210/4010 | 1.1 | |||||

| 400 | 570 | 4970/4730 | 1 | |||||

| 500 | 680 | 5940/5660 | 1 | |||||

| 630 | 810 | 6820 | 6 | 0.9 | ||||

| 800 | 980 | 8250 | 0.8 | |||||

| 1000 | 1150 | 11330 | 0.7 | |||||

| 1250 | 1380 | 13200 | 0.7 | |||||

| 1600 | 1660 | 15950 | 0.6 | |||||

| 2000 | 1950 | 19140 | 0.6 | |||||

| 2500 | 2340 | 22200 | 0.5 | |||||

Note: 1. The dimensions and weight are subject to change as required. The data in the two tables are subject to the factory documents. 2. For transformers with a rated capacity of 500kva and below, the load loss value above the diagonal line in the table applies to the Dyn11 or Yzn11 connection group, and the load loss value below the diagonal line applies to the Yyn0 connection group. 3. When the average load rate of the transformer is between 35%-40%, the highest operating efficiency can be obtained by using the loss value in the table. | ||||||||

Production Flow

Low-voltage foil winding area:

Case Storage Area:

Coil installation:

Assembly:

Testing:

Packaging & Shipping

After-Sales Service

1.Our company provides you with project design and process design, and designs and manufactures products according to your equipment purchase plan and specific needs. And train technical and operating personnel for you.

2.The newly purchased products are provided with online assistance for installation and debugging. The products are under the lifelong service system. If problems occur in normal use, we will provide solutions within one working day after receiving user's feedback. We will try our best to get the product up and running as soon as possible. And there are regular visits by professional technicians to ensure the long-term, safe and reliable use of our products.

3.We use quality authentic materials, process and manufacture in strict compliance with ISO9001:2000 international quality management to ensure the quality of excellence and the smooth installation!

Company Information

TSTY Electric Co., Ltd. was established in 2007 and is an excellent and reliable transformer manufacturer in China. The company mainly develops and produces oil-immersed transformers, dry-type transformers, box-type substations and high and low voltage complete sets of equipment.

The equipment put into production and operation of the project advocates energy saving, intelligence, information and mechanization. The company has established the Henan Triangle Energy-saving Transformer Engineering Technology Research Center, with 71 utility model patents and 15 invention patents.

With years of accumulation in the transformer industry and strong technological innovation capabilities, it provides comprehensive solutions for the Chinese power industry. The company is a key procurement unit for large-scale national projects such as State Grid, State Railway Administration, Zhengzhou Coal Group, Pingmei Group and South-to-North Water Diversion.