AP/-- ABB recently launched the SoliMold medium voltage cable accessory product series, which can be used in 1-35kV workplaces. The electrical withstand voltage performance is 30% higher than the national standard, and the installation time is significantly shorter than that of traditional products. It is suitable for power companies, petroleum and petrochemical companies, rail transit, wind and photovoltaic power plants, metallurgy, airports and other large power plants, silently guarding the stability of the urban power grid in subtle places.

At the World Expo in Chicago in 1893, Edison, the inventor at that time, was promoting his lighting system. The low-voltage cables for power supply were laid on the ground. The trampling of pedestrians, the rolling of carriages, and the connection points of cables and bulbs became extremely vulnerable to damage. Thomas and Betts, two young people who just graduated from MIT, had a keen insight into this phenomenon, and then invented the world's first cable protection device, and founded Thomas&Betts (now ABB) under this background.

"The birth of a great company began with small and important discoveries, just like the use of installation accessories is indispensable in the deployment of both electrical equipment and large power systems. Electrical installation products truly reflect how to ensure the high quality of electrical engineering from the smallest point, achieve great power industry, and help Chinese path to modernization grand goal." Said Dr. Dong Gang, head of ABB Electric China's installation products.

"High quality" installation enabling thousands of industries

In 2012, ABB completed the acquisition of Tongbei Company and became a global leader in the design, manufacturing and sales of industrial, construction and power industry installation products. So far, it has 38 high-quality sub brands, covering more than 200000 products, including ties, ports and connectors, support conduits and medium voltage cable components. "The installation products basically belong to where the electricity goes, they should go with the electricity. ABB installation products are widely used in various electric field complexes around the world," Dong Gang said proudly.

From the perspective of application, ABB installation products can be roughly divided into three categories: electrical management, connection and protection. In the application of electrical management, ABB is the inventor of the global cable tie. The standard Ty Rap cable tie was patented in 1958 and was originally developed for binding aircraft wiring. The tensile resistance, durability, low cost and easier installation of the tie are revolutionary inventions in the wiring industry. Since its inception, ABB has produced more than 30 billion cable ties. If these cable ties are connected end to end, they can travel between the Earth and the moon more than 10 times.

At present, there are more than 250 types of Ty Rap cable ties, and several materials can be selected. Its excellent performance has been fully verified in the ultra wide temperature range and extensive applications. ABB Ty Rap cable ties can be seen in 500 feet below sea level, 35000 feet in the air, or in the train running at more than 300 kilometers per hour, or in indoor or outdoor business and family scenes. ABB Ty Rap ties can also withstand the corrosion and radiation resistance requirements of space flight. NASA chose to widely use the Ty Rap ties in global commercial applications, such as fixing the internal and external conduits and components of the "Perseverance" Mars probe, to ensure the safety of research and laboratory equipment.

Equipped with ABB Ty Rap ™ NASA Perseverance rover with straps

Equipped with ABB Ty Rap ™ In terms of electrical connection and protection, ABB uses reliable and diversified solutions to meet the needs of different customers and help each industrial site establish a safe and convenient electricity environment. According to Dong Gang, during the epidemic, ABB cable components guaranteed part of the power supply system of a shelter hospital in Shandong, helping it to quickly build and put into use. Other products such as ABB AFX wire harness conduit and Narrow Tongue cold pressed end electrical auxiliary materials series can be applied to special equipment used in harsh environments, such as power generation, robots, food processing, refining, sewage treatment, rail locomotives, infrastructure, offshore drilling platforms, mines, wind power generation, solar power generation, off-road vehicles, etc.

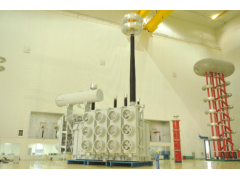

ABB SoliMold medium voltage cable accessory product series also "plays a big role" in the power supply system of the shelter hospital

ABB SoliMold medium voltage cable accessory product series also "plays a big role" in the power supply system of the shelter hospital, which is more related to the comprehensive cost and safety. High standards create the reliability and quality of the installed products

The platform of nine floors starts from the accumulation of soil. Looking forward to the modern industrial systems and future industrial models such as manufacturing power and quality power proposed by Chinese path to modernization, it puts forward a huge demand for the high-quality and high reliability of the underlying foundation and protection products, including various installation accessories. "Although there is no particularly complete standard or trade rule for auxiliary products in China, ABB has always advocated that electrical protection and control should adhere to higher product standards to ensure the safe use of electricity throughout the life cycle of the entire system." Dong Gang continued to emphasize: "In the final analysis, the high performance of the product is reflected in the higher security and reliability of the client. ABB's installed products can leave enough security redundancy in any harsh environment or in the working process to ensure the absolute safety of power consumption. At the same time, the product itself has excellent resistance and anti-aging."

Ensuring the safety and reliability of installed products is not a matter of the moment, but the first essence of ABB's more than 100 years of R&D and technological innovation. Up to now, ABB's diversified installation product series also have their own "security secrets".

For example, in order to make a seemingly inconspicuous small tie strip work in various extreme environments, even if it is deployed in a wind power plant at minus 40 degrees, it still provides normal performance without brittle cracks. It not only requires ABB tie strips to carefully match the material selection, but also benefits from maintaining full inspection during the manufacturing process. Even every the first mock examination needs to select 1-2 pin tie strips for destructive testing to ensure its reliability.

"If the product cannot find any failure or defect in the production and quality inspection process, it is equivalent to transferring the manufacturing cost that the manufacturer should bear to the user. If the manufacturer only needs to use 5 cents to improve each defect found, then the user will need to use more than 100 times the cost to repair and replace the defect found after deployment." Dong Steel uses a set of price comparisons to vividly express why the installation product must ensure the cost value of safety and reliability.

For lightning protection and grounding applications, the solutions of lightning protection and grounding system and surge protection system provided by ABB can comprehensively protect the safe, reliable and lasting operation of building power supply and distribution equipment. Among them, four-dimensional continuous electroplating method is adopted for copper plated conductors, and the thickness of any electroplating layer is greater than 0.25mm, with good conductivity and stable electrical performance.

For electrical connection products, ABB provides customers with process standardization ideas and reliable solutions from multiple dimensions such as production, manufacturing, experimental testing and factory inspection. For example, the raw materials of ABB terminal and cold pressed connector products use T1 copper as the raw material, the copper content is 99.99%, the surface of the terminal uses the tin plating process, and the coating thickness reaches 7 μ m. It provides better corrosion resistance for the end. At the same time, the product has passed the test standards of IEC60352 and IEC61238-1-Class B, meeting the CE certification. The relevant test standards will also make more stringent tests on the requirements of the temperature rise when the end is energized and the drawing force after crimping. Not only that, ABB uses color code identification on the end products, which is used in conjunction with the color code on the crimping die, to standardize the crimping from the perspective of technology, so as to avoid the installation personnel using wrong tools, resulting in the end not reaching the rated drawing force.

ABB crimp and mechanical connectors reflect multi-dimensional process standardization and reliability assurance

ABB crimped and mechanical connectors reflect multi-dimensional process standardization and reliability assurance. To meet the basic requirements of electromagnetic wire connection, ABB provides insulation layer puncture Dragon Tooth ® Crimp type terminals do not require welding, removal of insulation layer or special operation skills. They can be installed in seconds by using only the terminals and supporting tools. These terminals are made of copper alloy, tinned, and have many sharp teeth on the internal surface. When crimping the terminals to insulated electromagnetic wires, sharp and hard teeth will penetrate the insulation layer and oxides and bite the wires, The reliable low resistance connection is established by the high strength pressure at the tip and edge of the sharp tooth and the sliding between the sharp tooth and the wire.

"In ABB's view, the reliability of the product still needs to be reflected in the integrated system, because the connector and cable are a system after crimping, and the connection point should not be a weak point on the cable, but should be a point with connection reliability in the whole system." Dong Gang further explained: "Even if cables with uneven quality are used, after crimping with ABB products and tools, the mechanical strength of the connection point should be at least equal to that of the cable itself, the conductivity should be better than that of the cable, and the temperature rise should not be greater than any point of the cable."

link global resources and deepen local innovation and product portfolio advantages

China is still recognized as one of the markets with fast growth, multiple opportunities and complex diversity. As one of the important business units of ABB Electric, installation products need not only to introduce high-quality products into the Chinese market, but also to make Chinese customers realize the importance of installation accessories for the entire electric and gas system and industrial chain. Dong Gang said that as a new entrant in the Chinese market, ABB's installation products are rooted in localization and innovation, which is also a product development strategy that ABB has always adhered to. Through these years' efforts, ABB has launched products like seismic support, lightning protection and grounding system materials and other very "grounding gas" products for the Chinese market, which have been recognized by customers.

The rapid development of economy has accelerated the process of urbanization in China, and the height and scale of modern buildings are constantly breaking new records. These magnificent buildings put forward higher requirements for the seismic performance of non structural members of the project. ABB is based on load mechanics, and the checking calculation of seismic action is the core. Through ABB Superstrut with efficient connectors ® The support products, as well as the customized, stable and economical disaster resistance protection scheme, build a safe and convenient anti-seismic "fortress" for mechanical and electrical facilities such as pipes, air ducts, cable trays, etc., and maintain the original working state no matter how the building shakes, which is also the mandatory content of the new national standard.

ABB Superstrut bracket products are widely used to build safe and convenient anti-seismic "fortress"

ABB Superstrut bracket products are widely used to build a safe and convenient anti-seismic "fortress". Since the third-party test report is an important basis for measuring the performance of bracket products, ABB bracket products pay attention to the reducibility of the parameter performance in the test report on site. Therefore, in the design and manufacturing process, we adhere to the use of high-quality steel from large steel plants, put an end to the use of negative tolerance materials, and ensure that the laboratory performance is restored to the construction site. It is worth mentioning that ABB quick lock products can greatly improve the installation speed of the opposite crossing when assembling the seismic support, reduce the installation difficulty and construction intensity, save installation time and significantly reduce the installation cost compared with traditional solutions.

There are more than 8 million lightning strikes every day in the world, and the loss of electrical protection equipment or improper protection will cause casualties and major economic losses. ABB complies with IEC62305 standard, and specifically introduces Furse copper plated round steel solution for the Chinese market, providing safe, reliable and cost-effective lightning protection solutions for Chinese customers. Furse lightning protection scheme can realize long service life, lower annual use cost, less maintenance workload and more convenient construction mode, so that the risk of personal injury and death loss is less than 10-5, the risk of public service loss is less than 10-3, and the risk of cultural and genetic loss is less than 10-4. It is one of the safer and more reliable lightning protection systems in the world.

In fact, every time a circuit breaker or switch cabinet is sold, there will be sales opportunities for installing accessories or connectors, and even the installed products have a larger market share and capacity than electrical products. Dong Gang predicted that the future installation products have huge growth potential in both the global and Chinese markets. In particular, ABB Electric has deployed a very stable and efficient distribution network in China. The installation products can not only enjoy the dividends brought by the sales network, but ABB will also, as always, rely on more than 100 years of global R&D experience of installation products and local innovation of resource empowerment to provide a more complete product portfolio and services for the Chinese market.