Overview

Essential details

Place of Origin:

Jiangsu, China

Brand Name:

THIM

Model Number:

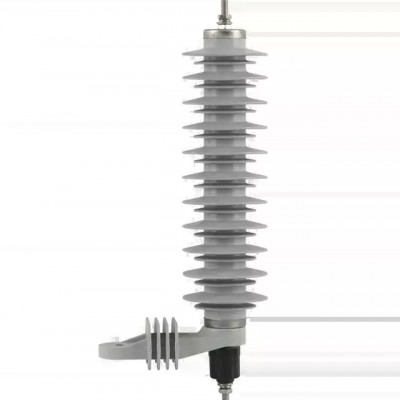

FXBW 4 -33/70

Type:

Insulator

Material:

Composite Polymer

Application:

High Voltage

Rated Voltage:

33KV

Tensile Strength:

8KN-120KN

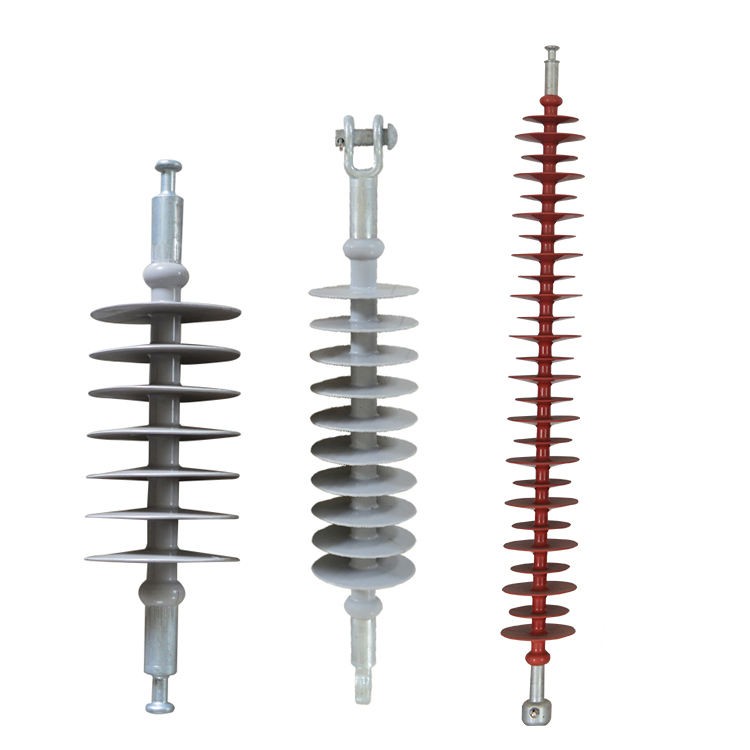

color:

Red,light gray ,blue or customized

key words:

Composite Suspension Insulator

Product name:

33kv Reinforce Suspension Composite insulator power line

Feature:

small size,light weight,high tensile strength.anti pollution

advantage:

Good pollution/aging resistance,high mechanical strength

Size:

Customized Size

Supply Ability

Supply Ability

1000 Piece/Pieces per Week

Packaging & delivery

Packaging Details

cartons or according to your requirement for 33kv Reinforce Suspension Composite insulator power line

Port

Shanghai

Lead time:

Quantity(pieces) 1 - 100 >100 Lead time (days) 15 To be negotiated

33kv Reinforce Suspension Composite insulator power line

Our main products are as follows:

1.10kv -750kv silicone rubber insulator

2.Diam.5-180mm Insulator core rod(epoxy resin rod)

3.Many kinds of insulator fittings such as ball,socket,Tongue,Clevis,Flange and so on.

4.Silicone rubber

our website : http://thim.en.alibaba.com/

Product Description

Type | No. Of Sheds | “X” Length inches (mm) | Diameter Inches (mm) | Leakage Distance Inches (mm) | Dry Arc Distance inches (mm) | Lighting withstand voltage | Wet power frequency voltage | Coupling size | SML Pounds (kN) | |

D | d | |||||||||

FXBW-10/70 | 4 | 310 | 105 | 75 | 350 | 152 | 90 | 40 | 16 | 70 |

FXBW-36/40 | 9 | 440 | 130 | 90 | 950 | 320 | 230 | 150 | 16 | 40 |

FXBW-36/100 | 9 | 483 | 130 | 90 | 950 | 320 | 230 | 150 | 16 | 100 |

FXBW-35/70 | 12 | 660 | 135 | 110 | 1600 | 526 | 230 | 150 | 16 | 70 |

FXBW-35/100 | 12 | 680 | 135 | 110 | 1600 | 526 | 230 | 150 | 16 | 100 |

FXBW-66/70 | 20 | 980 | 135 | 110 | 2500 | 826 | 410 | 185 | 16 | 70 |

FXBW-66/100 | 20 | 1000 | 135 | 110 | 2500 | 826 | 410 | 185 | 16 | 100 |

FXBW-66/120 | 20 | 1040 | 135 | 110 | 2500 | 826 | 410 | 185 | 16 | 120 |

FXBW-110/70 | 26 | 1190 | 135 | 110 | 3500 | 1050 | 550 | 250 | 16 | 70 |

FXBW-110/100 | 26 | 1210 | 135 | 110 | 3500 | 1050 | 550 | 250 | 16 | 100 |

FXBW-110/120 | 26 | 1250 | 135 | 110 | 3500 | 1050 | 550 | 250 | 16 | 120 |

FXBW-220/120 | 54 | 2470 | 150 | 120 | 6300 | 2130 | 1000 | 395 | 16 | 120 |

FXBW-220/210 | 56 | 2470 | 170 | 120 | 6300 | 2155 | 1000 | 395 | 20 | 210 |

1. Shed connected with core by integral foring

2. The thinkness of housing > 3mm,unifirm to IEC Standard

3. Acid resistant,hight temperature resistant of epoxy fiberglass core

4. metal end fittings,core and sheds connected by new crimping process

5. Hot galvanization and technology of rareearth aluminum coating to avoid coating

shedding prolonging the service life

verified

verified