Production description

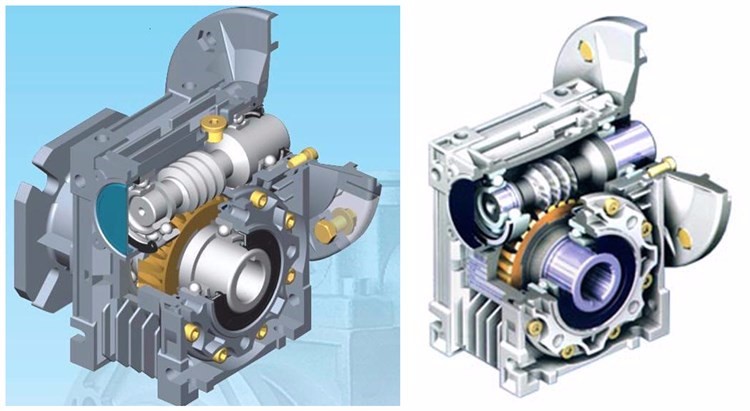

A:Structure Features

1.High quality die casting aluminum alloy housing, suitable for universal mounting.

2.Heat sink design for cooling provides great surface area and higher thermal capacity

than the casting iron housings.

3.025 to 150, with power scope from 60W to15KW.

4.Larger speed ratio range. Each single frame size has 12 ratios from 5:1 to 100:1.

5.Hardened worm with fine grinding has the features of higher efficiency and big output torque.

6.Low noise and stable running, can adapt long term work condition in terrible environments.

7.Light weight, high mechanical strength.

8.Modularization combination PCRW and DRW extend the ration RW reducers from i=5:1 to 3200:1.

B:Main materials

Housing:

die-cast aluminum alloy (frame size: 025 up to 90) , cast iron(frame size: 110 to 150).

Worm: 20Cr steel, carburization and nitriding treatment(the hardness of tooth is HRC60).

Worm wheel: special wearable nickel bronze alloy.

C:Paint

Aluminum alloy housing:

1.Shot blasting and special antiseptic treatment on the aluminum alloy surface.

2.After phosphating, coated with blue RAL5010 baking finished.

D:Cast iron housing:

painted with RAL5010 blue baking finished.

Details

Packing & Delivery

verified

verified